Surface Finishing Services

Surface finish is a term that refers to the process used to alter a metal's surface by adding, removing or reshaping. The goal is to protect the metal and improve the aesthetic side. The result depends on the metal finishing method. Often, there are a few different ways to achieve the same or similar results

Surface finishes can range from smooth and shiny to rough and non-reflective. A few common surface finishes usually consist of specialty Hairlines, Etching, Mirror polishing, Powder coating, Electroplating, Painting, Anodizing and Patina.

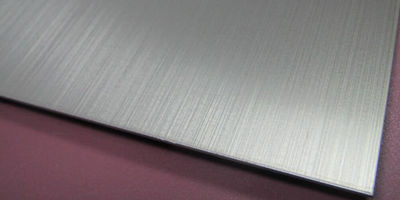

Hairlines Finish

Hairlines Finish was obtained by endless grinding lines extend uniformly along with the length of coil or sheet. It's a well-defined directional finish with long and fine line. It's widely used in elevator panels, escalators, automotive sector, interior cladding, building facades and other architectural applications

Etching

Etching The etching removes a thin layer of stainless steel, changes the color to a dull silver gray, and roughens the surface, which can be contrasted with grinding, super mirror or other finishes to create thousands of variations. Etched finish also can be colored before or after etching.

Mirror polishing

Mirror polishing Stainless steel mirror polishing is a surface treatment of stainless steel tubes, pipes and any kind of Stainless steel fabricated items. It is a finish that is smooth enough to provide a reflective surface. After polishing stainless steel tubes by many different processes, the mirror quality of stainless steel obtained is usually 6K or better.

Powder coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. Powder coating protects the roughest, toughest machinery as well as the household items you depend on daily. It provides a more durable finish than liquid paints can offer, while still providing an attractive finish.

Electroplating

Electroplating is a general name for processes that produce a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current, Electroplating is primarily used to change the physical properties of an object. This process can be used to give objects increased wear resistance, corrosion protection or aesthetic appeal, as well as increased thickness. While electroplating may seem like advanced technology, it is actually a centuries-old process.

Paint

Paint doesn’t stick as well to a metal surface as it does to wood or plaster. Also, metal is prone to oxidation and rust. When painting on metal, it's essential to use a formulated paint for metal, especially if you want to control rust and weathering. Metal paints come in oil-based and water-based versions.

Anodizing

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. The process is called anodizing because the part to be treated forms the anode electrode of an electrolytic cell, Anodizing is an electrolytic process for producing thick oxide coatings, usually on aluminum and its alloys. The oxide layer is typically 5 to 30µm in thickness and is used to give improved surface resistance to wear and corrosion, or as a decorative layer.

Patina

Patina is a finish over a surface that develops over a period of time due to weather, stress and/or age. It is often used to refer to objects made of metal that develop a green film as a result of chemical reactions, as well as rust. However, the term can encompass any type of material, from metal to wood to leather.